What are the advantages of using a structured-light 3D scanner?

No Contact Required with the Scan Target

Structured-light 3D Scanners are non-contact 3D scanners, meaning the measurement device does not touch the object in order to get measurement data compared to other measurement tools like portable or optical CMMs. This minimizes measurement interference due to physical contact to ensure better accuracy.

Fast at Capturing Quality 3D Scans at High Accuracy

Structured-light 3D scanners are efficient at capturing measurements (upward of millions of 3D measurement points) with great accuracy (sub-thousands of an inch) in about one second.

Full Field Scanning

A structured-light 3D scanners capture a large area of the object at once, which makes the 3D scanning process fast and efficient.

Easy to Automate the 3D Scanning Process

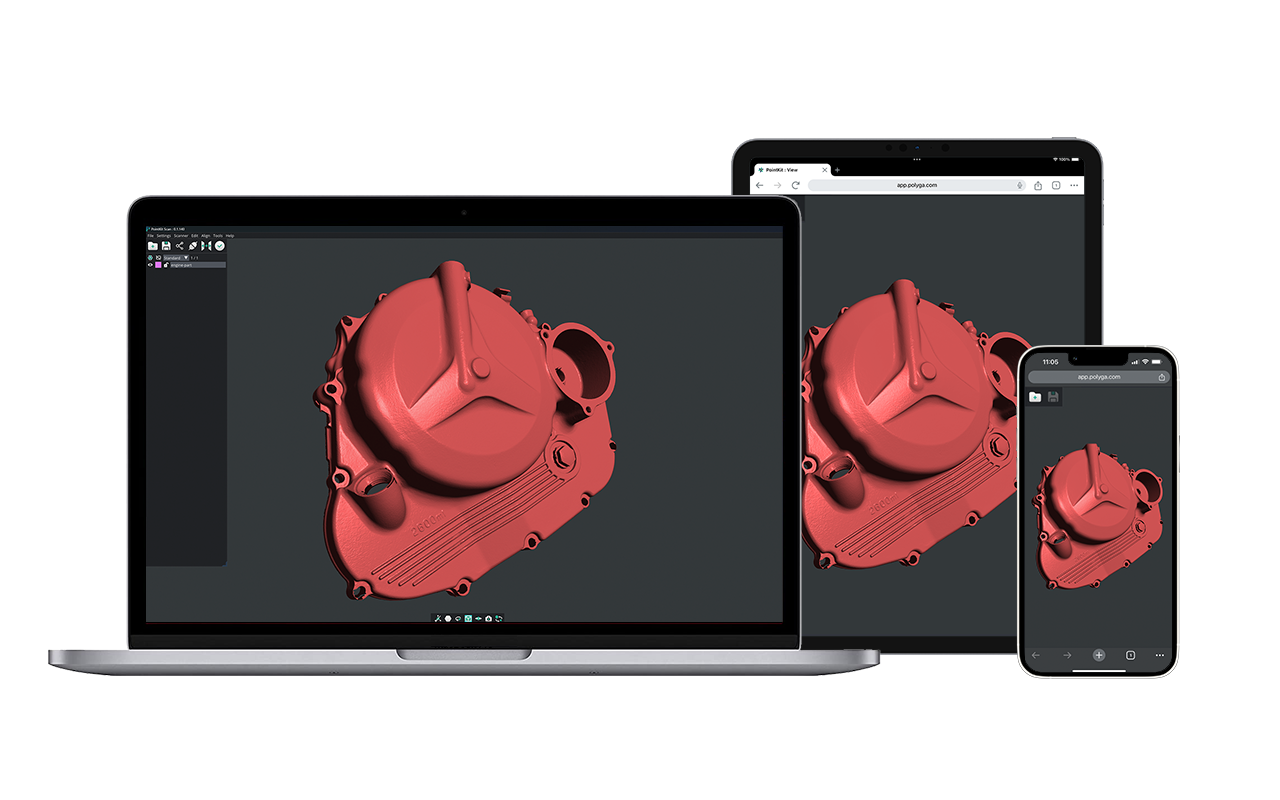

Structured-light 3D scanners essentially works like a 3D camera. If the system is pre-calibrated for accuracy during the manufacturing process, minimal setup is required to start the scanning process. The 3D scanning process from data capture to post-processing can be setup to be fully automated. It makes structured-light 3D scanners an ideal candidate to integrate into systems or embedding into devices.

Stationary 3D scanners versus handheld 3D scanners

Stationary structured-light 3D scanners require capturing unit to remain still when taking a 3D scan of an object. Handheld structured-light 3D scanners require someone to hold the capturing unit and wave it around the object to capture scans.

While handheld scanners are convenient to use, if you want better scan data quality stationary structured-light 3D scanners outperform handheld 3D scanners, in terms of accuracy and resolution.

The reason is handheld 3D scanners capture scans like a video camera, so they capture a scan while the 3D scanner is moving. Stationary 3D scanners stay still while capturing a scan. You capture better results when you take a stationary 3D scan versus a moving 3D scan.

Basically the trade-off for using a handheld 3D scanner is convenience over higher accuracy and detail of a stationary 3D scanner.

Structured-light 3D scanners versus laser 3D scanners

They are both optical 3D measurement devices that uses light-based measurement techniques to capture a 3D scan. Laser 3D scanners gather data using a laser line or a point at a time while structured-light 3D scanners uses white or blue light technology to capture the entire area using multiple patterns and images (full field scanning).

Structured-light 3D scanners have the following advantages over laser 3D scanners:

- Faster scan times

- Produce dense and accurate data

- Higher detail levels

- Takes the full view of the object with full field scanning

- Safe for people, even to the naked eye